Waya Woyera wa Molybdenum Thermal Spray for Galling and Scuffing Resistance

Mtundu ndi Kukula

Zhaolixin Tungtsen & Molybdenum imatha kupereka waya wa molybdenum malinga ndi zojambula zanu ndi zofuna zanu.

| Diameter (μm) | Kulemera (mg/200mm) | Kulemera (mg/200mg) Kulekerera (%) | Kulekerera Diameter (%) | ||

| Gulu 1 | Gulu 2 | Gulu 1 | Gulu 2 | ||

| 20≤d<30 | 0.65-1.47 | ±2.5 | ±3 | ||

| 30≤d <40 | > 1.47 ~ 2.61 | ±2.0 | ±3 | ||

| 40≤d<100 | > 2.61 ~ 16.33 | ±1.5 | ±3 | ||

| 100≤d <400 | > 16.33 ~ 256.2 | ±1.5 | ±4 | ||

| 400≤d <600 | ±1.5 | ±2.5 | |||

| 600≤d <3200 | ±1.0 | ±2.0 | |||

Mawonekedwe

| Katundu | Metric | Imperial |

| Mphamvu yamphamvu (yowonjezera) | 324 MPa | 47000 psi |

| Mphamvu ya kukameta ubweya (kuvuta kwa 0.25 / s) | 500 MPa | 72500 psi |

| Kuchuluka kwa mphamvu zokolola (0.01% zokolola) | 400 MPa | 58000 psi |

| Modulus ya elasticity | 330 GPA | 47900 pa |

| Modulus ya elasticity pa kutentha kokwezeka (@2000°C/3630°F) | 160 GPA | 23200 ndi |

| Thermal Coefficient of Expansies: | 5 x 10-6 cm/cm @ 25 oC | |

| Mphamvu yamagetsi: | 34% IACS | |

| Thermal Conductivity: | 1.38 W/cm/K @ 298.2 K | |

| Kukanika kwa Magetsi: | 5.2 microhm-cm @ 0 oC | |

Mo-waya ndi wakuda wakuda wokutidwa ndi graphite.Pambuyo pochotsedwa graphite ndi zitsulo zonyezimira.

Mapulogalamu

- Kwa makina odulira waya

- Zopangira zida zamagetsi zamagetsi ndi zida zamagetsi zamagetsi

- Popanga zinthu zotenthetsera ndi zida za refractory m'ng'anjo zotentha kwambiri

- Kwa kupopera mbewu mankhwalawa mbali zina zagalimoto ndi makina ena kuti awonjezere kuvala kwawo

- La2O3 kapena Y2O3 doped Refractory Mo-waya zilipo

Mmisiri

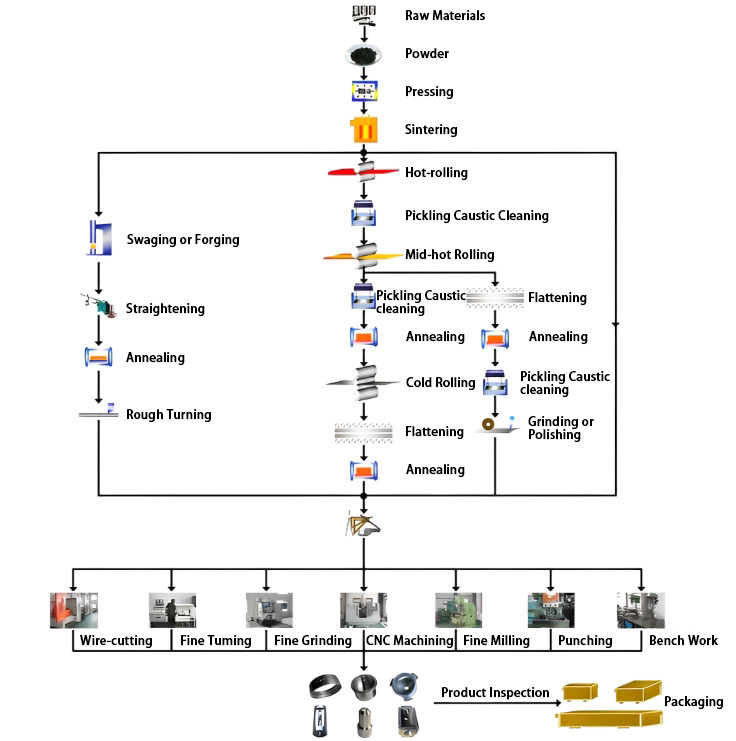

Zopangira:Kuyambira pazida zopangira, timasankha zida zapamwamba kwambiri, zomwe zimawonekera kwambiri pakukhazikika komanso kusasinthika kwazinthu.Dziwani mitundu yosiyanasiyana ya zida ndikuyika nambala ya batch.Ndipo gulu lililonse la zipangizo adzakhala sampuli, anayendera ndi archived.Onetsetsani kutsatiridwa kwa chinthu chilichonse chomwe chamalizidwa ndikuwongolera mosalekeza mtundu wake.

Ufa:Ulamuliro wa ndondomeko mphero Zhaolinxin Metal mankhwala ndi yolondola kwambiri, ndi mixers angapo lalikulu ndi kugwedera nsanja kuonetsetsa kuti zipangizo mu pulverizing ndi kusanganikirana ndondomeko akhoza mokwanira analimbikitsa ndi wogawana anagawira, kuti kuonetsetsa kugwirizana mkati bungwe la mankhwala.

Kuthamanga:Popanga ufa, ufawo umakanikizidwa ndi zida zosindikizira za isostatic kuti mawonekedwe ake amkati akhale ofanana komanso owundana.Zhaolixin ili ndi nkhungu yabwino kwambiri, komanso ili ndi zida zosindikizira za isostatic kuti zikwaniritse kupanga magulu akuluakulu azinthu.

Sintering:Muzitsulo za ufa, pambuyo pa chitsulo chachitsulo chopangidwa ndi kukakamiza kwa isostatic, kumatenthedwa ndi kutentha pang'ono kusiyana ndi kusungunuka kwa zigawo zazikuluzikulu kuti tinthu tigwirizane, kuti tipititse patsogolo ntchito za mankhwala, zomwe zimatchedwa sintering.Pambuyo popanga ufa, thupi lowundana lomwe limapezedwa ndi sintering ndi mtundu wazinthu za polycrystalline.The ndondomeko sintering mwachindunji zimakhudza mbewu kukula, pore kukula ndi mbewu malire malire mawonekedwe ndi kugawa mu microstructure, umene ndi pachimake ndondomeko ufa zitsulo.

Kupanga:Njira yopangira zinthu imatha kupangitsa kuti zinthuzo zikhale zolimba kwambiri, zida zabwino zamakina, ndikuthandizira kulimbikitsa pamwamba.Kuwongolera moyenera kuchuluka kwa ma processing ndi kutentha kwa tungsten ndi molybdenum ndizofunikira kwambiri pakuchita bwino kwa Zhaolixin tungsten ndi molybdenum.Njira yogwiritsira ntchito makina opangira makina kuti agwiritse ntchito kukakamiza chitsulo chopanda kanthu kuti chiwonongeko kuti chiwonongeko kuti chipezekepo ndi zinthu zina zamakina, mawonekedwe ndi kukula kwake.

Kugudubuza:Kugubuduza kumapangitsa kuti zinthu zachitsulo zitulutse mapindikidwe apulasitiki mosalekeza mokakamizidwa ndi mpukutu wozungulira, ndikupeza mawonekedwe agawo ndi katundu wofunikira.Ndi ukadaulo wapamwamba wa tungsten ndi molybdenum ozizira komanso otentha akugudubuza ndi zida, kuchokera ku tungsten ndi zitsulo za molybdenum zopanda kanthu mpaka kupanga zojambulazo za tungsten ndi molybdenum, Zhaolixinguarantees inu luso lapamwamba kwambiri lopanga komanso zitsulo zapamwamba kwambiri.

Kutentha-Kuchiza:Pambuyo popanga ndi kugubuduza, zinthuzo zimayendetsedwa ndi njira yochizira kutentha kuti zithetseretu kupsinjika kwamkati kwazinthu, kupereka kusewera kwazinthu, ndikupangitsa kuti zinthuzo zikhale zosavuta kwa Machining wotsatira.Zhaolixin ili ndi ng'anjo zambiri zowulukira ndi kutentha kwa ng'anjo ya haidrojeni kuti ikwaniritse kutumizidwa mwachangu kwa malamulo opangira zinthu zambiri.

Makina:Zhaolixin zakhala zikuchitidwa kutentha kwathunthu, kenako zimasinthidwa kukhala makonda osiyanasiyana ndi zida zopangira makina monga kutembenuza, mphero, kudula, kugaya, etc., ndikuwonetsetsa kuti gulu lamkati la tungsten ndi molybdenum ndi lolimba, lopanda nkhawa. ndi zopanda dzenje, zomwe zingakwaniritse zosowa za makasitomala.

Chitsimikizo chadongosolo:Kuyang'ana kwaubwino ndi kuwongolera kudzachitika kuchokera kuzinthu zopangira komanso pagawo lililonse la kupanga, kuti nthawi zonse zitsimikizire mtundu wa chinthu chilichonse.Panthawi imodzimodziyo, pamene zomalizidwa zimaperekedwa kuchokera ku nyumba yosungiramo katundu, maonekedwe, kukula ndi bungwe lamkati la zipangizo zimayesedwa chimodzi ndi chimodzi.Choncho, kukhazikika ndi kusasinthasintha kwazinthu ndizodziwika kwambiri.